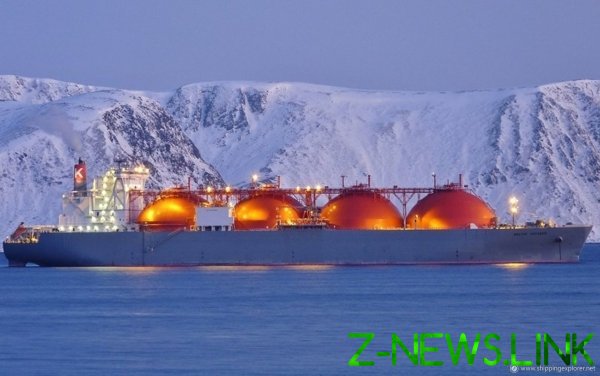

Despite coronavirus crisis in Russia continues to implement ambitious projects aimed, primarily, at increasing export potential of the country. In the Arctic, off the coast of Yamal, in the autumn should stand up for production watch the first of the floating plants flotilla “Flatmates”. For methanol as a “fuel of the future” rely many industrialized countries, and Russia, in that informal race to claim a strong lead.

Plans “Flatotel” are impressive: the capacity of the flotilla must issue at least 10 million tons of methanol per year, compounded for that 15 billion cubic meters of natural gas. Experts agree in opinion that such an ambitious project will be one of the main drivers of download the Northern sea route, the tasks which President Putin was elevated to the rank of major project. The NSR of the Russian methanol production – a direct route to China and other Asian countries, the world’s largest consumers “fuel of the future.” In addition, plants “Flatotel” will perform the function of bunkering and filling stations, thus creating the infrastructure needed for the new model ships, engines which run on methanol.

In mid-March, Federal Institute of industrial property” (FIPS) adopted a positive decision on the issuance of “Flumethasone” patent for invention No. 2020111497 “Device for producing methanol of high concentration”. This device will work on the company’s vessels, the first of which is scheduled to be operational next summer. But it is only part of a whole “bunch” of modern technology, which is planned to implement the project. Technology note, only Russian, and all the equipment, which are equipped with floating plants. This, the company will provide the project the necessary economic profitability and reduce the risks of sanctions.

Equally responsible here approaches to addressing issues related to the impact of methanol production on the environment. The environmental aspect of such projects is always one of the most sensitive, therefore, to possible criticisms the company has prepared thoroughly – not in the sense of answers, and technologically. “Technology plan, according to the website of the company, provides for almost complete utilization of the waste gas and the periodic system – the purge and tank gases are used as fuel in the burner tube furnace methane conversion and generated in the process of cooling the converted gas and gas condensate is directed to the process for the production of steam”. In the language of modern environmentalists this is called zero waste or non-waste production.

The only component of the system that require special disposal, are catalysts: as a tryout, according to a strict schedule they will change and take on a special site for safe recycling.

With the commissioning of the first floating factories “of Flumecinol” Russia will state a substantial claim to leadership in the world “methanol race”. The idea is to produce methyl alcohol “afloat” is not new, but significant activity in this area has emerged only at the beginning of last decade, when the economic benefits from the use of methanol as fuel in fully felt shipowners. Then it became obvious that to accommodate the production capacity of methanol need as close as possible, not only to the gas fields and transit terminals, but also to the Maritime trade routes.

What if to produce methanol on floating plants, which simultaneously can serve as a bunkering and filling stations for ships of a new type? One of the first term, praised the Norwegians in the company Solco at the end of “zero” has developed the project of a special vessel for stand-alone methanol production in the open sea with a capacity of approximately 1 million tonnes/year. Moreover, their combined floating unit can simultaneously carry out sea and associated gas production, and methanol production from the same.

Russia, in turn, is actively developing gas fields in the Arctic zone, and, despite the harsh natural conditions, the produced natural gas, we have one of the cheapest in the world. According to the analytical Agency Vygon Consulting, the cost of raw materials for the production of one ton of methanol in Russia in 2019 was $ 65. Cheaper only in Saudi Arabia – $ 48. In the U.S., for example, the 113 dollars in Trinidad and Tobago, where the plant is Methanex – the world’s largest producer of methanol, 93 per dollar in Iran is $ 97.

That is, the idea of building Autonomous floating plants and “dock” them to a gas pipe somewhere off the coast of Yamal, we can say, waiting for his investor. And such was the young Russian company “Flatmates”.

In early may, the global Agency said the signs of recovery of the market from the “pandemic of the pit”: the methanol recovered from the crisis one of the first. In China, which accounts for nearly half of global methanol consumption (41%, according to 2017), the price of this product increased by $ 5 compared to April.

According to experts, in the coming years, at least until 2030, the demand for methanol and other products of gas chemistry will grow steadily. Will grow and prices on average by 5% per year, and this growth, in contrast to oil prices, of particular volatility is not threatened. This means that the oil dependency of the Russian economy will become even weaker in the light of recent developments, it becomes extremely important for the country.

© 2020, paradox. All rights reserved.